กลับหน้าน้ำมันและก๊าซธรรมชาติ 02 มีนาคม 2563 |

In order to enhance efficiency, a company has introduce a wellhead automation monitoring system for its natural gas production

In order to enhance efficiency, a company has introduce a wellhead automation monitoring system for its natural gas production

The data that is most valuable to energy companies includes gas flows and temperatures when gas is being dispatched from the fields. Once the oil company has extracted this data, it will usually transmit the data to the control center via a cellular communications link where the operator can then perform data analysis. However, every time the servers in the control center send a request to the field sites for new data it will cost the oil company money. One way to avoid the cost of transmitting so much data is to store data at the local site when an event is triggered. Another pain point for the company is that the cabinets they use cannot accommodate a cellular router, a data logger, and a remote I/O due to space constraints. Therefore, a smart data acquisition solution that can provide multiple functions and fit in the limited space will have significant advantages over other solutions.

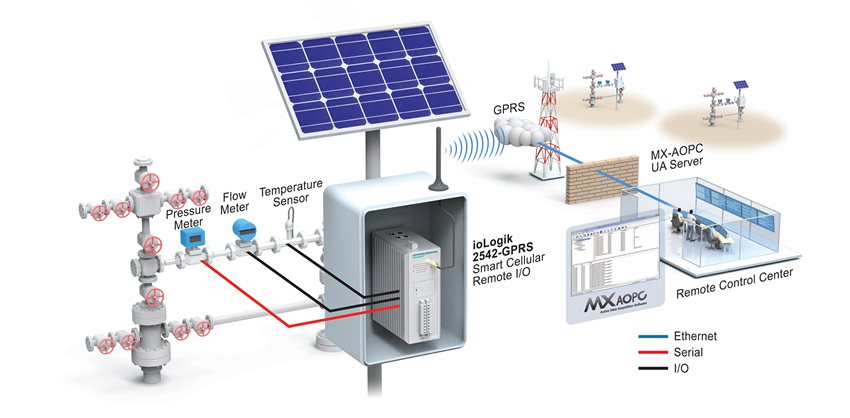

Deploying cellular communications between the gas fields and the control center will reduce the upfront infrastructure cost and also increase efficiency. Moxa’s ioLogik 2542-GPRS smart remote I/O is a 4-in-1 data acquisition solution including a data acquisition device, Modbus gateway, an unmanaged switch, and a data logger. Moxa’s ioLogik 2500 has a cellular communication module and VPN function that can connect meters and sensors at field sites, as well as transmit data via a cellular connection. Therefore, the company doesn’t need to install cellular routers or switches in the small cabinet and the devices can be powered via solar panels, further reducing the total cost of ownership.

The smart remote I/O and the MX-AOPC UA server work together to intelligently manage the data logs by scheduling active messages to be automatically pushed from the ioLogik 2542-GPRS to the SCADA systems at the control center. This smart data acquisition takes places when the I/O state changes or pre-configured events occur, allowing information to be accurately and efficiently pushed to the SCADA system as it becomes available without having to request additional data from the control center.

To ensure the integrity of critical data, the ioLogik 2542-GPRS has two functions to prevent data loss. The first is that a smart remote I/O allows the company to save I/O tags and serial tags locally in the micro SD card at certain intervals to avoid data loss if the GPRS connection fails. If the connection does fail, the company can retrieve data from the FTP to avoid data loss due to the disrupted connection. In addition, the smart remote I/O can also record the counter value of gas wells even when the power is disconnected. When the power resumes, it can continue counting values based on the last recorded value.

With Click&Go Plus control logic, the ioLogik 2542-GPRS allows the company to easily set up alerts, the data logger, and acquisition mechanisms. Even when deploying hundreds of smart remote I/Os at field sites, the company can still complete the project effortlessly.

Long-Distance Wireless Communications for Pipeline Monitoring

Building a Modern Drilling Chair to Help Lower the TCO

น้ำมันและก๊าซธรรมชาติ

Oil & Gas

โรงงานอุตสาหกรรม

Manufacturing

พลังงานและสาธารณูปโภค

Power & Public utility

งานขนส่งอัจฉริยะ

Intelligent Transportation

งานขนส่งระบบราง

Rail

งานขนส่งทางทะเล

Marine

KVM Extenders

KVM Extenders

COLD CHAIN MONITORING

COLD CHAIN MONITORING

เมืองอัจฉริยะ

Smart City

แพลตฟอร์มคอมพิวเตอร์ เอไอ

AI Computing Platform